Disposable gloves in the world of professional hygiene

Find all the prices for single-use disposable gloves made of nitrile, vinyl, latex, etc., from manufacturers, and compare standards . Understand what you use and buy, and more specifically the qualities and weights that determine the price of your glove.

The manufacture of disposable gloves is mainly located in Asian countries such as China, Malaysia, Thailand , etc. However, the French manufacturer Kolmi , part of the Mondial Medicom group, decided after the Covid19 pandemic to restart the manufacture of nitrile gloves in France with the most demanding quality standards.

This is a response to regaining strategic independence for this sensitive range of personal protective equipment. Voussert, just like its range of disposable masks made in France, had to offer this alternative.

Understanding the materials of single-use disposable gloves

The materials are of several types and depend on the context of use but also on the tolerance of users to certain materials (in particular, be careful of latex allergies).

Price is also a factor. Nitrile is a material that varies greatly, with prices sometimes doubling or even tripling depending on the production context.

- Natural rubber latex in powdered or powder-free finish. Made from rubber

Natural, these gloves offer excellent dexterity, extreme sensitivity and high resistance to breaking. Repeated exposure and direct contact of latex with the skin can cause significant risks of allergies .

- Vinyl made of polyvinyl chloride plastic in a powdered or powder-free finish. Vinyl gloves are used as an economical alternative to latex and nitrile gloves. Vinyl gloves are not suitable for prolonged contact with fatty substances under the standards related to

food contact.

- Synthetic rubber nitrile in powdered or powder-free finish. Nitrile gloves combine

many advantages and an increasingly competitive quality/price ratio . They are:

1. Hypoallergenic to reduce the risk of allergies

2. Comfortable to provide optimal dexterity in wet and dry conditions

3. Mechanically resistant to avoid overconsumption

4. Compatible with certain foodstuffs

- Stretch plastic material in polyvinyl chloride, powdered or powder-free

- Synthetic polyethylene and powder-free polyethylene

Understanding the standards for professional disposable gloves

These requirements concern ergonomics, construction, safety, comfort, effectiveness, marking and information leaflet; they are applicable to all protective gloves.

The concept of glove standards is important because it must correspond to the use and the field of application.

There are therefore three main areas:

Use as a medical device (MD) with the EN 455 standard protects the patient and healthcare personnel against the risk of infection.

Use as personal protective equipment (PPE) with standards EN 420, EN 374, EN 16523 which protects the operator against an external risk.

Use as hygiene equipment with Regulation (EC) 1935/2004 of 27 October 2004.

European Standard EN 455: Single-use medical gloves (Medical Device)

EN 455-1:2020+A2:2024 Requirements and tests for freedom from holes

Gloves must pass a watertightness test for hole detection. This test is carried out on a statistical sample (taken in accordance with ISO 2859-1) whose acceptance criterion is an acceptable quality level (AQL) and less than 1.5.

EN 455-2:2024 Requirements and tests on physical properties

This standard specifies the requirements and methods

EN 455-3:2023 Requirements and tests for biological evaluation

This standard describes requirements and test methods for assessing the biological safety of medical gloves, as part of a safety management process.

risks, in accordance with EN ISO 14971 and EN ISO 10993.

This involves assessing factors such as:

1. Endotoxin content (for sterile gloves only)

2. The quantity of powder

3. Chemical compounds used in manufacturing processes - accelerators, antioxidants,

biocides

4. Extractable proteins (for latex gloves)

5. Biocompatibility (according to EN ISO 10993 standards)

| Surgical gloves | Latex nitrile examination gloves | Vinyl examination/procedure glove, PE |

| Tear strength in Newtons | > 9.0 | >6.0 | >3.6 |

EN 455-4:2009 Determination of shelf life

This standard is used to determine the use-by date, the date beyond which the glove can no longer be used while guaranteeing the integrity of its physical properties.

The maximum lifespan of a medical glove is 5 years from the date of manufacture.

EN ISO 21420:2020+A1:2024 general requirements for PPE gloves

This standard defines the general requirements and test methods applicable to all protective gloves. It includes:

1. the ergonomics and construction of the glove

2. the resistance of the constituent materials to water penetration

3. safety

4. comfort and efficiency

5. the marking and information provided by the manufacturer

Standard EN374-1: 2016+A1:2018 disposable gloves against chemicals

This series of standards covers protective gloves that claim protection against chemicals and microorganisms.

The EN 374-1 standard distinguishes two levels of glove penetration: penetration and permeation.

The standard is based on 3 test methods:

I Penetration test according to EN ISO 374-2:2019

I Permeation test according to EN 16523-1:2015+A1:2018

I Degradation test according to EN ISO 374-4:2019

How is the glove's resistance to contact with a chemical product determined?

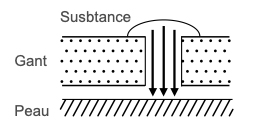

| Penetration | Permeation | Degradation |

Penetration describes the passage of a product

chemical through the imperfections of the

material or the porosities and joints of the glove.

Glove penetration resistance

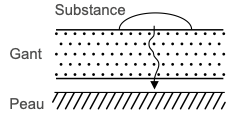

| Permeation is diffusion, on a scale

molecular, chemical through

the material the glove is made of.

Permeation disposable glove

| Degradation is about determination

resistance to degradation by

chemicals

Degradation = transformation with

deterioration of one or more

glove material properties, continued

in contact with a chemical product,

e.g. flaking, swelling,

disintegration, embrittlement, discoloration,

dimensional variations, hardening,

softening, etc. |

Penetration test on disposable gloves EN 374-2:2014

This test aims to analyze the glove's watertightness, by measuring its level of

air and water leaks. The result, consistent with both tests, allows us to claim

performance: “waterproof glove providing protection against microorganisms”, recognizable by a specific pictogram.

Gloves bearing this pictogram are considered an effective barrier against bacteria and fungi.

NB: This does not apply to virus protection.

Standard EN 16523-1:2015+A1:2018 protection against chemical permeation

Chemical permeation test EN 16523-1:2015+A1:2018

Chemical risk corresponds to the passage of the substance through the glove. The migration of chemical molecules through the glove is determined by the passage time (in minutes) of the chemical substance inside the glove. The choice of glove is based on its performance level (breakthrough time), which determines whether it belongs to a type of protection (A, B, or C).

Type A : The pictogram may only be affixed to the product or its packaging if the glove has achieved performance level “2” for a minimum of 6 tested chemicals, from the table below. The “letter codes” of the chemicals that have achieved performance level “2” are listed below the pictogram.

Type B: The pictogram may only be affixed to the product or its packaging if the glove has achieved performance level “2” for a minimum of 3 tested chemicals from the list opposite. The “letter codes” of the chemicals that have achieved performance level “2” are listed below the pictogram.

Type C : The pictogram can be affixed to the product or its packaging only if the glove has obtained performance level “1” for at least one tested chemical product, from the list below.

The chemical(s) tested must be indicated in the instructions for use.

The choice of glove is based on its level of performance (permeation time) which determines whether it belongs to a class:

Official list of chemicals registered for the EN 16523-1 standard

| Code | chemical product | CAS number | Class |

| HAS | Methanol | 67-56-1 | Primary alcohol |

| B | Acetone | 67-64-1 | Ketone |

| C | Acetonitrile | 75-058 | Nitrile compound |

| D | Dichloromethane | 75-09-2 | Chlorinated hydrocarbon |

| E | Carbon disulfide | 75-15-0 | Organic compound containing sulfur |

| F | Toluene | 108-88-3 | Aromatic hydrocarbon |

| G | Diethylamine | 109-89-7 | Amine |

| H | Tetrahydrofuran | 109-99-9 | Heterocyclic etheric compound |

| I | Ethyl acetate | 141-78-6 | Ester |

| I | n-Heptane | 142-82-5 | Saturated hydrocarbon |

| K | Sodium hydroxide 40% | 1310-73-2 | Inorganic base |

| L | Sulfuric acid 96% | 7664-93-9 | Inorganic mineral acid, oxidant |

| M | Nitric acid 65% | 7967-37-2 | Inorganic mineral acid, oxidant |

| N | Acetic acid 99% | 64-19-7 | Organic acid |

| O | Ammonia 25% | 1336-21-6 | Organic base |

| P | Hydrogen peroxide 30% | 7722-84-1 | Peroxide |

| S | Hydrogen fluoride 40% | 7664-39-3 | Inorganic mineral acid |

| T | Formaldehyde 37% | 50-00-0 | Aldehyde |

Degradation test according to EN 374-4 standard

Resistance to degradation (DR) shall be determined according to EN 374-4 for each chemical claimed in the marking, and recorded in the user instructions.

It takes into account the effects of the chemical on the materials making up the glove. Degradation can take the form, for example, of brittleness, swelling or shrinkage of the glove.

Standard EN 374-5: 2016 disposable glove against microorganisms

Protective glove against microorganisms: gloves forming a protective barrier against microbiological agents (bacteria, viruses, molds).

Gloves must pass the leak test according to EN ISO 374-2:2019.

The possibility of claiming protection against viruses is added if the glove passes the ISO 16604:2004 test (method B).

For gloves providing protection against cytotoxic agents (chemotherapy drugs) must meet ASTM D6978-05.

The EN 421:2010 standard is suitable for gloves providing protection against radioactive particles.

Standard EN388:2016 disposable glove against mechanical risks

Glove providing protection against at least one of the following mechanical risks: abrasion, cutting by slicing, tearing and perforation

The first 4 digits under the EN 388 logo

- Abrasion resistance 0 -> 4

- Cutting resistance 0 -> 5

- Tear resistance 0 -> 4

- Puncture resistance 0 -> 4

New on EN388:2016

- C Cut EN ISO 13997

- (P) Impact protection

The higher the level, the better the protection.

X means no test was performed

Single-use disposable glove suitable for food contact

The “glass/fork” symbol on the boxes indicates the glove’s ability to come into contact with food.

Single-use disposable gloves according to European regulations

This capacity is governed by European Regulation No. 1935/2004.

Specific measures have been taken regarding plastic objects, gloves are governed by EU Regulation 10/2011.

Migration tests are carried out according to these texts, 4 families of foodstuffs are tested:

for aqueous foods

for acidic foods

for alcoholic foods

for fatty foods

Use of disposable gloves

The information provided by the manufacturer must comply with the information requirements of EN 420. It must also include the results of penetration, degradation and permeation tests, + the list of all chemicals for which the gloves have been tested and the performance obtained during the permeation tests.

The following warnings should be added to the user instructions:

- "This information does not reflect the actual duration of protection in the workplace, nor the differentiation between mixtures and pure chemicals."

- "Chemical resistance was assessed under laboratory conditions using samples taken only from the palm (except in cases where the glove cuff of a length greater than or equal to 400 mm was also tested) and only concerns the chemical product under test. It may differ if used in a mixture."

It is recommended to check that the gloves are suitable for the intended use, as workplace conditions may differ from those of the typical test, depending on temperature, abrasion and degradation.

“When used, disposable gloves may offer less resistance to hazardous chemicals due to altered physical properties. Movement, snags, friction, or degradation caused by contact with chemicals, etc., can significantly reduce the actual duration of use. For corrosive chemicals, degradation may be the most important factor to consider when selecting chemical-resistant gloves.

“Before use, it is recommended to inspect disposable gloves for any defects or imperfections.”

For multi-use gloves, the manufacturer must provide appropriate instructions for decontamination.

If there is no information on decontamination, then the glove is intended for single use only and the following warning must be added: “For single use only”.

_UK_